“ EXPERT IN CURVED ROOF AND WALL CLADDING ”

Specials

Dupral is able to produce a wide variety of special products:

- Rolling flat sheets (both straight and conical)

- Forming cassette panels

- Producing smooth prefab corner sections

Rolled covers

Rolled covers are produced to the required radius using a 3-roller rolling mill. It is also possible to produce conical products. Additional forming work on the rolled cover is of course also possible.

Covers can be made from steel, aluminium, copper and zinc. Maximum thickness is 3.0 mm.

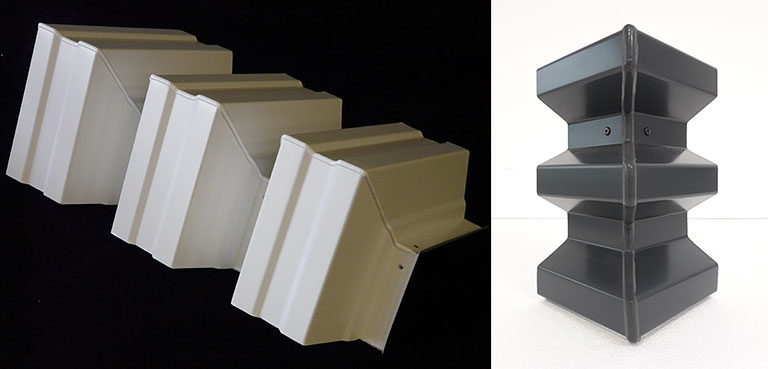

Cassettes

Cassettes are punched from flat sheets and are then formed. They can be produced to any required size, including corner sections to any required angle.

Assembly is fairly simple because only the top needs to be fixed, with the next section being placed on top of the section just fixed (male/female).

For larger sizes there is the option of bonding Eps to the inside, which results in a smoother appearance. Maximum thickness is 3.0 mm.

Corner sections

Corner sections of every imaginable angle – both internal and external – can be made from any required profile.

First the angle is sawn, then the sawn profiled sheets are formed to the required angle. They are secured with a diagonal on the inside using pop-rivets, in order to maintain the angle.

Finally, the corner piece on the outside is finished with a thin sealant bead ( possibly in the colour of the sheet).